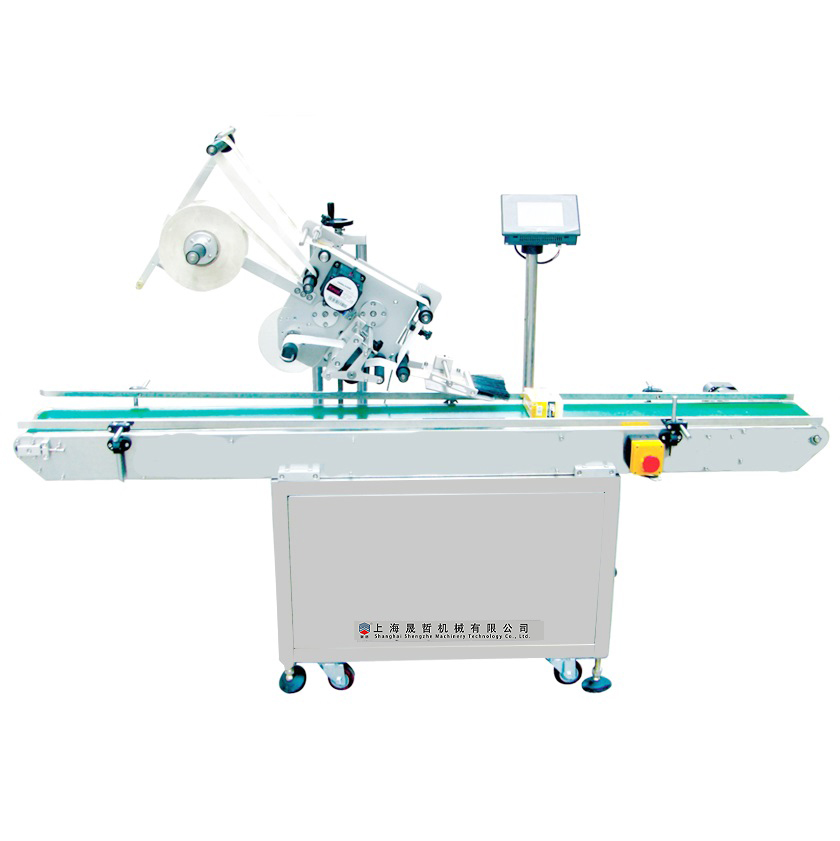

Suitable for applying labels or adhesive films on the upper surfaces of various items, such as books, folders, boxes, cartons, etc. The labeling mechanism can be replaced to accommodate uneven surfaces, widely used for flat labeling of large products, and for labeling large flat objects within a wide range of specifications. Optional integration of coding machines or inkjet printers with the labeling head allows printing of production dates, batch numbers, and barcode information on the labels.

Applicable labels: Self-adhesive labels, adhesive films, electronic supervision codes, barcodes, etc.

Applicable products: Products requiring labeling or film attachment on flat or large curved surfaces.

Application industries: Widely used in printing, stationery, food, daily chemicals, electronics, pharmaceuticals, and other industries.

Application examples: Flat labeling of books, folder labeling, packaging box labeling, board labeling, etc.

| project | parameter |

| Applicable label range | Height: 15-180mm Length: 10-250mm |

| Maximum label size | Outer diameter: 320 mm Inner diameter: 76 mm |

| Labeling speed | 1-80 pieces/minute (speed adjustable) |

| Labeling accuracy | ±1mm (excluding errors of attached objects and labels) |

| power, power | 220V /50-60HZ1.8KW |

| Dimensions | L2000mm×W650mm×H1550mm |

| equipment weight | About 350kg |

| Conveyor belt width | Customized according to product |

| Conveyor belt to floor level | 750mm plus or minus 30mm |

| Conveying direction | left → right |

1. High labeling accuracy, driven by subdivided servo motors for precise label feeding; designed with a label deviation correction mechanism to ensure labels are pulled without deviation during traction; eccentric wheel technology applied to the traction mechanism prevents label slipping, ensuring accurate label application.

2. Sturdy and durable, utilizing a five-bar adjustment mechanism to fully utilize the stability of five-axis positioning, resulting in a solid and durable machine.

3. Easy adjustment, with adjustable seats for freedom of design, simplifying and saving time during product transitions.

4. Touch screen operation interface, comprehensive fault prompt function, simple and quick parameter adjustment, easy operation.

5. Intelligent control, with automatic photoelectric tracking, capable of labeling any object, automatic correction in the absence of labels, and automatic label detection to prevent missed labeling and label waste.

6. Flexible application, can be used for standalone production or integrated into a production line, with a simple layout on the production site.

7. Powerful functions, including production counting, power-saving functions, production number setting prompt functions, parameter setting protection functions, facilitating production management.

Shanghai Shengzhe Mechanical Technology Co., Ltd. was founded in 2003 and is a professional manufacturer integrating production, engineering, and trade. After 10 years of forging, it has gradually formed packaging equipment with pharmaceuticals, food, cosmetics, and other products as its main products: high-speed cartoning machines, transparent film three-dimensional packaging machines, transparent film bundling machines, integrated box opening, packing, and sealing machines, fully automatic unmanned bundling machines, as well as multifunctional pillow-type packaging machines, labeling machines, wrapping machines, wrapping machines, filling and sealing machines, extrusion sheet machines, paper bowl machines, bowl sticking machines, disc box machines, capping machines, cup stacking machines, molds, and other diverse series of electromechanical fully automated machinery and equipment.